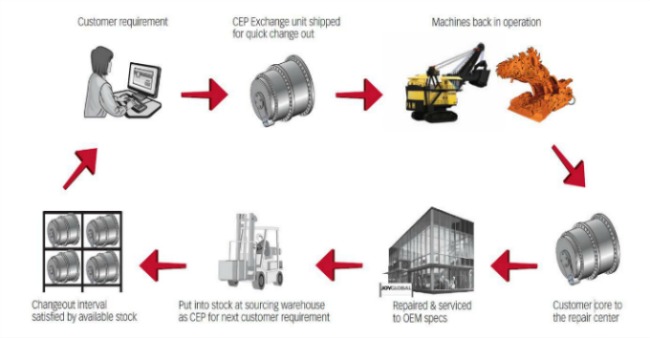

You can only achieve your production goals if your machines remain in operation. Minimizing machine downtime is critical since, if maintenance actions are not done quickly, your production goals can be hindered. With the Component Exchange Program (CEP), you have a ready supply of like-new, re-manufactured P&H and Joy components available for same-day or next-day delivery.

We have CEP components available for:

- Surface: drills, draglines, shovels, wheel loaders, and haul trucks

- Underground: continuous miners, bolting systems, entry development, conveyor products, longwall systems, feeder breakers, and haulage systems

- Hard rock: loaders, trucks, utility vehicles, shaft sinking, and drills

In addition, our component exchange program also includes select components for haul trucks and non-P&H shovels, wheel loaders, drills, and draglines.

Reduces operating costs

The Component Exchange Program helps reduce your operating costs through:

- Limited downtime: costly downtime is limited to the time required to replace the failed component, compared to the duration of a full repair

- Limited inventory: the need to carry costly inventory is eliminated since component inventory is managed by our service centres; regional warehouses around the globe are available 24/7 to accommodate your needs

- Reduced component costs: the costs of an exchange component can be significantly less expensive than a new component

- New warranty: your exchange component comes with a OEM-backed warranty that matches or exceeds that of new components

- Newest technology: your exchange component is totally re-manufactured to original equipment specifications, following exacting standards, and incorporating the latest OEM design improvements

Our re-manufacturing process

In our Component Exchange Program, components are re-manufactured to original equipment specifications, incorporating the latest in design improvements.

The re-manufacturing process begins with the complete disassembly of the component, followed by a thorough steam cleaning and bead/sandblasting of transmission cases and motor frames.

Then a comprehensive inspection is carried out that includes a failure/wear analysis, gear and spline auditing, and an alignment of motor frames and gearboxes. All rebuilt motors are processed through vacuum pressure impregnation (VPI) to ensure reliable internal insulation.

To minimize the possibility of any defects, non-destructive testing is carried out on all load-bearing assemblies and working mechanical components using a magnetic-particle check, black light inspection, and/or ultrasound inspection. Parts requiring repairs are either brought back to original OEM specification or replaced to restore the assembly to like-new condition.

Our electrical testing is just as rigorous as our mechanical checks and non-destructive testing. Electrical operation and integrity are evaluated on all circuit boards, logic circuits, armatures, rotors, interpoles, fields, brushes, commutators, coils, wiring, electrical connections, and ground straps. If any part fails to meet OEM specification, the part or subassembly is replaced. Our state-of-the-art electronic components are repaired and warrantied by our OEM supplier, ensuring the same level of performance as new components.

After repairs are made and parts are replaced, the components are tested to replicate real-world applications. Armatures, fans, dipper trips, and other high RPM components are re-balanced and tested, while all motors are load tested and have vibration spectrums measured and analysed. Hydraulic components are tested at optimum speeds and pressures, brakes are cycled, and transmissions rotated to ensure optimal field performance.

When the component has passed all testing procedures, it is put into stock at a warehouse, waiting for the next customer’s need.